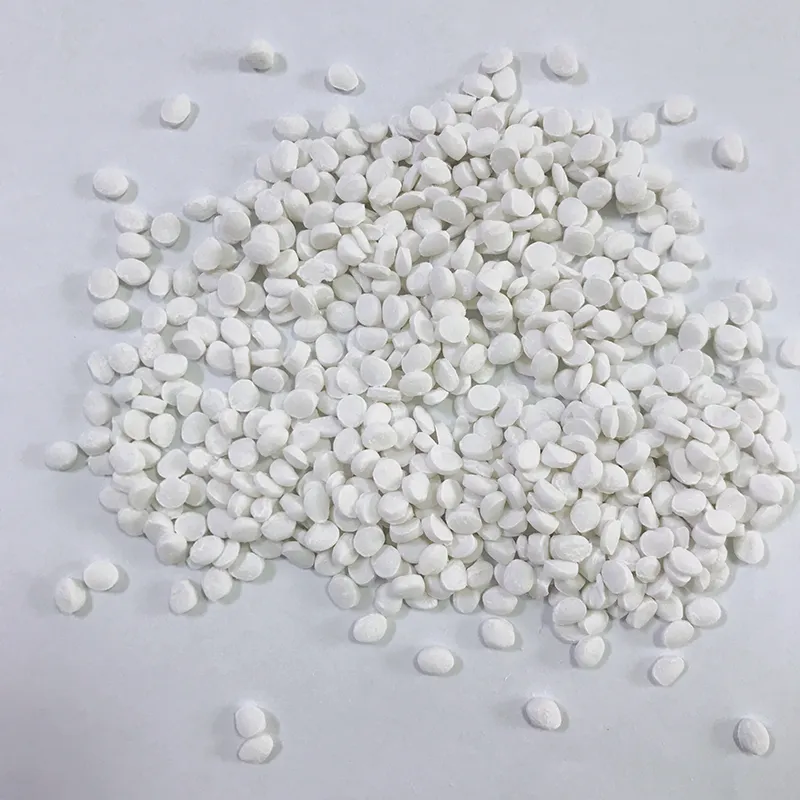

Defoamer Masterbatch

Send Inquiry

Defoamer Masterbatch Product Introduction:

The following is the introduction of high quality Defoamer Masterbatch, hoping to help you better understand it. Welcome new and old customers to continue to cooperate with us to create a better future! raw materials containing trace moisture or moisture has a very serious impact on the production of plastic products, so enterprises generally use drying equipment to dry the plastics, which is a great waste of energy and manpower, increasing the production of products The production cost of the antifoaming masterbatch can eliminate all the problems such as bubbles, moire, cracks and spots caused by moisture by adding it into the raw material and stirring evenly without any adjustment of the production process of the product.

Defoaming masterbatch Performance and advantages:

High water absorption, high weather resistance, fast flow rate, uniform dispersion, good compatibility, no needle spots, no fog, no net blocking, no dust, migration resistance, aging resistance, tensile resistance, corrosion resistance, easy dilution, easy to mix, suitable for automated production.

Defoamer Masterbatch Application:

The role of defoaming masterbatch: It’s mainly used to remove moisture and unknown low molecular volatiles contained in plastics, without causing air and water bubbles, so as to skip the drying process while guarantee the quality of products.

Calcium Oxide Masterbatch is widely used in a variety of plastic products, such as below:

Film blowing: shopping bags, films

Blow Molding: car oil bottles/container

Extrusion Molding: sheet,pipe,wire&cable

InjectionMolding:automative,electronic,construction,house wares,furniture,toys