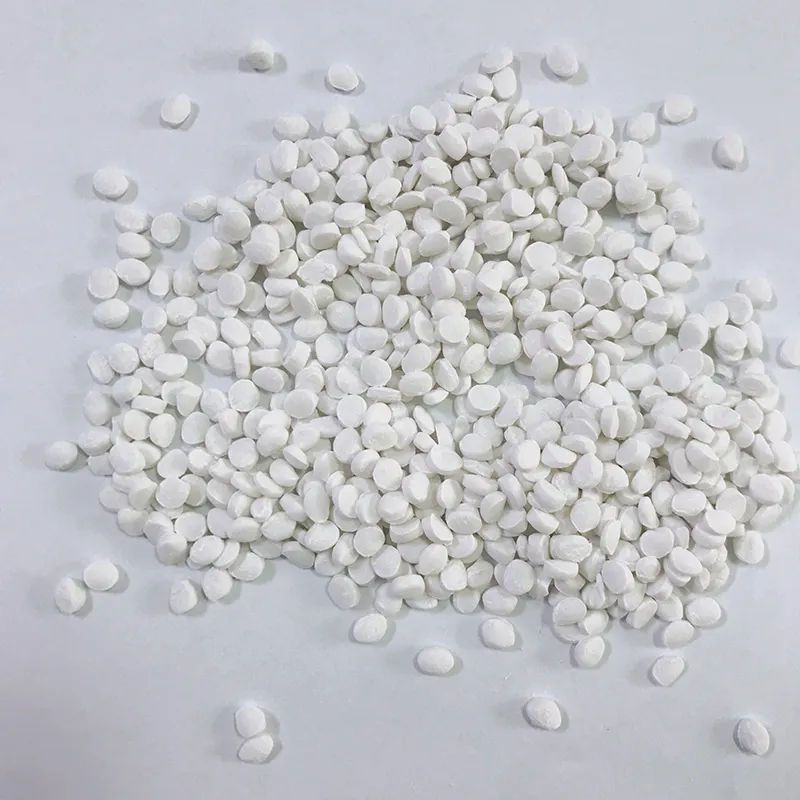

Filled Masterbatch

Send Inquiry

Product Description: China Filled Masterbatch is a plastic processing aid composed of carrier resin, fillers (such as calcium carbonate, talcum powder) and additives (dispersants, surface treatment agents, etc.), mainly used in the production of polyolefin products. It is made into granules by premixing high-concentration fillers and resins, and the base resin is added in proportion during plastic molding to optimize processing performance and reduce costs. The carrier resin should be compatible with the matrix resin and have a suitable melting point, while the additives ensure the uniform dispersion of the fillers. This material is widely used in fields such as films, woven bags, and injection molded products. It can enhance rigidity and reduce shrinkage rate, but it may affect transparency and toughness.

The development of Filled Masterbatch has gone through three generations of process iterations: The first generation adopted random polypropylene carriers and intermittent internal mixing processes; The second generation adopted LDPE resin and a special single-screw extruder. The third generation uses polypropylene powder or blends as the carrier and combines the hot cutting and air-cooling technology of the mold surface to enhance efficiency. The application of twin-screw extruders has enabled continuous production, reduced energy consumption and enhanced stability. With technological advancements, functional masterbatches (such as color masterbatches and degradable masterbatches) have been continuously expanding their application scenarios and now cover multiple fields including film tear resistance, pipe manufacturing, and engineering plastics.