Flame-retardant Masterbatch

Send Inquiry

Product Description: Flame-retardant Masterbatch (also known as flame-retardant masterbatch or fireproof masterbatch) is a functional additive material designed to enhance the fire resistance of plastic, rubber and other products. It is made by combining brominated, halogenated and other flame retardants with carriers for modification and then extruding and granulation. Its core function is to achieve flame retardancy. The coverage mechanism includes heat absorption, inhibition of chain reactions, etc. It features good dispersibility, high flame retardant efficiency and little impact on the mechanical properties of materials, and can replace traditional powdered flame retardants.

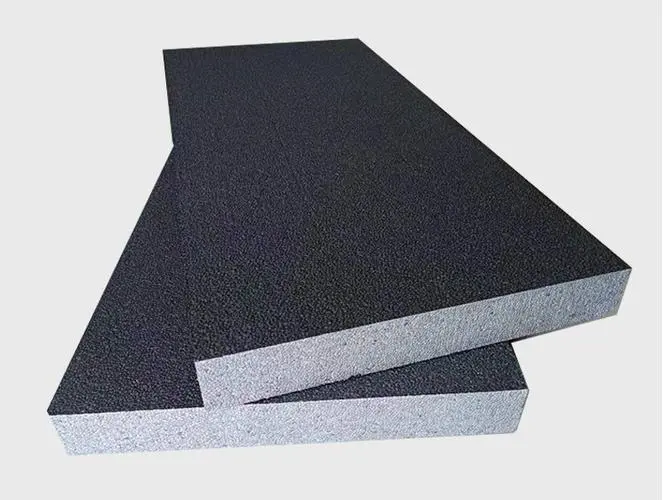

Flame-retardant masterbatches are classified into four major categories: halogen-based, phosphorus-based, nitrogen-based (intumescent type), and inorganic. Halogen-based ones have high flame-retardant efficiency but lack environmental friendliness. Phosphorus-based ones show significant effects in specific resins but have compatibility limitations. Inorganic ones are environmentally friendly but require high addition amounts. With technological advancements, flame-retardant masterbatches have developed into a series of products for resins such as polyethylene and polypropylene (such as drawing grade and extrusion grade), and are widely used in fields like construction, electronics, automobiles, and medical devices through customized formulas. Typical applications include safety nets, cables, battery components for new energy vehicles, and lightweight materials for high-speed rail. Environmentally friendly halogen-free flame retardant masterbatches are gradually becoming the development trend of the industry due to their low smoke and non-toxic characteristics.

What are the advantages of our products?

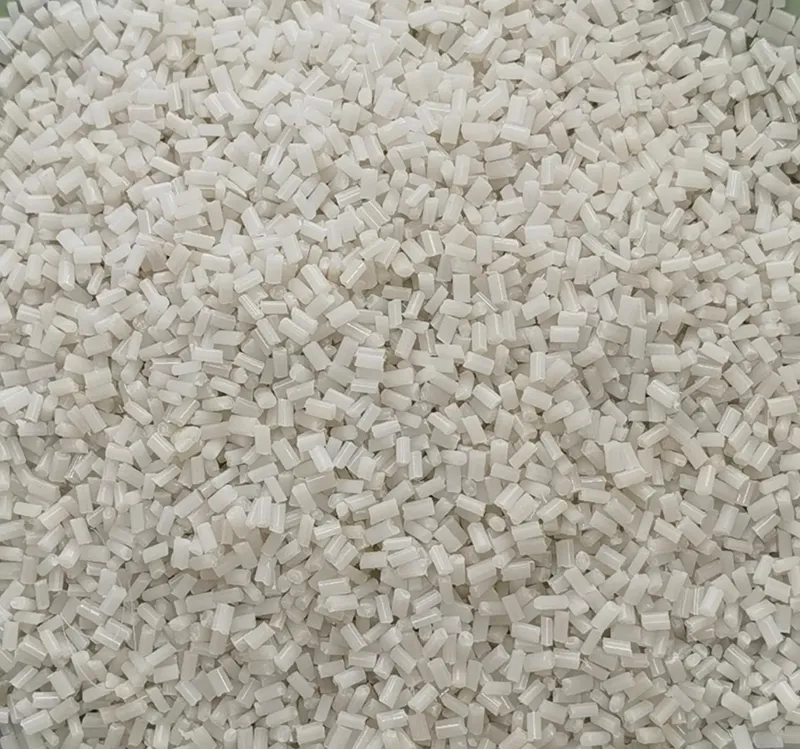

1. Easy to use: Flame-retardant Masterbatch is mostly in the form of sheet or strip-sized granules, which are exactly the same size as general plastic granules. This enhances their mutual compatibility, making them easier to disperse and add, hygienic and reducing volatile waste.

2. Good compatibility with resins: Generally, flame-retardant masterbatches undergo special treatment, which enhances their compatibility with plastic resins. This ensures that even when added in large amounts to the resins, they are less likely to cause problems such as delamination, frosting, and patterns.

3. Reduce costs and increase product added value: Often, by adding flame-retardant masterbatches, general plastics can meet or approach the application requirements of engineering plastics, thereby increasing product added value and reducing raw material costs.